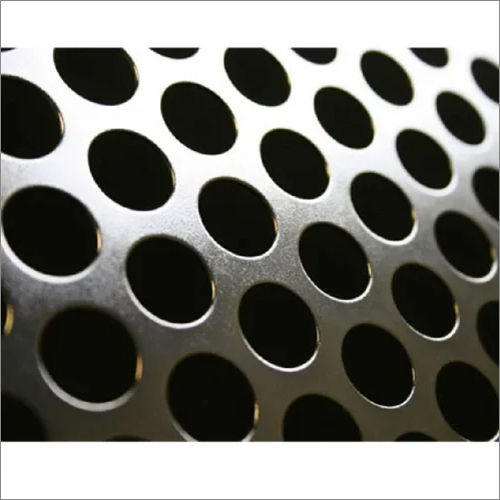

Round Hole Perforated Sheet

Product Details:

- Shape Sheet (Rectangular, Square)

- Temper Hard, Soft (as required)

- Process Punching / Perforation

- Standard ASTM, ISO

- Surface Treatment Galvanized, Powder coated, Polished

- Usage Industrial

- Material Metal

- Click to View more

Round Hole Perforated Sheet Price And Quantity

- 10 Square Foot

- 165 INR/Square Foot

- Depends on sheet size and thickness

- Standard metallic and custom colors

- As per client specification

- 1 m x 2 m, 1.25 m x 2.5 m, customized sizes available

- Yes

- 0.5 mm to 25 mm

- Wooden Pallet, HDPE Wrapping

- Straight, Smooth

- 10% to 60%

Round Hole Perforated Sheet Product Specifications

- Punching / Perforation

- Sheet (Rectangular, Square)

- Industrial

- Hard, Soft (as required)

- High strength, Durable, Uniform perforation

- Round Hole Perforated Sheet

- Perforation

- Industrial, Filtration, Ventilation, Acoustic control

- ASTM, ISO

- Metal

- Galvanized, Powder coated, Polished

- 0.5 mm to 8 mm (customizable)

- Depends on sheet size and thickness

- Standard metallic and custom colors

- As per client specification

- 1 m x 2 m, 1.25 m x 2.5 m, customized sizes available

- Yes

- 0.5 mm to 25 mm

- Wooden Pallet, HDPE Wrapping

- Straight, Smooth

- 10% to 60%

Round Hole Perforated Sheet Trade Information

- 100000 Square Foot Per Month

- 7 Days

- All India

Product Description

Round Hole Perforated Sheets are metal sheets that have been punched with a pattern of round holes. These sheets are widely used in various applications due to their aesthetic appeal and functional benefits.

Material Options:

- Stainless Steel: Known for its corrosion resistance and durability.

- Aluminum: Lightweight and corrosion-resistant, often used for decorative purposes.

- Mild Steel: Affordable and suitable for less demanding environments.

- Galvanized Steel: Coated for enhanced corrosion resistance.

Features:

- Hole Size: Round holes can vary in diameter, typically ranging from 1 mm to 50 mm or more.

- Hole Spacing: The distance between holes (pitch) can be customized based on the application.

- Sheet Thickness: Available in various thicknesses, usually from 0.5 mm to 6 mm.

- Sheet Size: Common sizes are 1000 mm x 2000 mm and 1200 mm x 2400 mm, but custom sizes can be ordered.

- Pattern: Regular or staggered hole patterns, depending on design requirements.

Applications:

- Architectural: Used in facades, ceilings, and decorative panels.

- Industrial: Used for filters, sieves, and screens.

- Ventilation: Ideal for grilles and ventilation covers.

- Decorative: Adds a modern touch to interiors and exteriors.

FAQs About Round Hole Perforated Sheets:

1. What are the benefits of using round hole perforated sheets?

- Aesthetic Appeal: Provides a clean, modern look.

- Versatility: Suitable for a wide range of applications from decorative to functional.

- Strength and Durability: Maintains structural integrity while allowing airflow and light.

- Customizability: Can be tailored to specific design and performance needs.

2. How do I choose the right round hole perforated sheet for my project?

- Material: Choose based on environmental conditions and strength requirements (e.g., stainless steel for high-corrosion environments).

- Hole Size and Spacing: Select based on the desired level of light, airflow, or aesthetic effect.

- Thickness: Consider the load and stress the sheet will be subjected to.

3. Can round hole perforated sheets be customized?

- Yes, they can be customized in terms of hole size, spacing, sheet dimensions, and material. Many suppliers offer custom manufacturing to meet specific needs.

4. How do I maintain and clean round hole perforated sheets?

- Regular Cleaning: Use mild soap and water for routine maintenance.

- For Tough Stains: Use non-abrasive cleaners suitable for the material.

- Avoid Harsh Chemicals: Chemicals like bleach or ammonia can damage the finish.

5. Are round hole perforated sheets suitable for outdoor use?

- Yes, they can be used outdoors, especially if made from corrosion-resistant materials like stainless steel or aluminum. Ensure that the finish is suitable for the environment to enhance longevity.

6. What are the common hole sizes and patterns available for round hole perforated sheets?

- Hole Sizes: Typically range from 1 mm to 50 mm in diameter.

- Patterns: Include regular (equidistant) and staggered (offset) hole arrangements.

7. How are round hole perforated sheets fabricated?

- Punching: Holes are created using a punching machine or die.

- Customization: For specific needs, custom dies or laser cutting may be used.

8. What industries commonly use round hole perforated sheets?

- Construction and Architecture: For building facades, decorative elements, and ceiling panels.

- Manufacturing and Industry: For filters, sieves, and grilles.

- HVAC: For ventilation covers and grilles

Precision and Versatility

Designed for superior performance, these Round Hole Perforated Sheets feature uniform holes and customizable specifications. Suitable for a variety of industrial applications, including filtration, ventilation, and acoustic management, they deliver consistent quality and adaptability for demanding environments.

Durability and Surface Treatment Options

Crafted from high-strength metals and available in thicknesses from 0.5 mm to 8 mm, these sheets offer outstanding durability. Multiple surface treatments, such as galvanizing, polishing, and powder coating, enhance corrosion resistance and aesthetic appeal, making them ideal for long-term industrial use.

Customized Solutions for Industry

Fulfilling ASTM and ISO standards, these sheets can be tailored to client needs through custom sizing, hole diameter, open area, pitch, color, and temper. Professional packing ensures safe delivery, while the products versatility meets the specifications of dealers, exporters, distributors, and manufacturers across India.

FAQs of Round Hole Perforated Sheet:

Q: How are Round Hole Perforated Sheets manufactured for uniformity?

A: These sheets are produced using precise perforation techniques, such as punching, to ensure consistent hole diameter and alignment. Custom patterns and pitches are implemented according to client specifications, guaranteeing uniform perforation and meeting rigorous quality standards.Q: What are the available size and hole diameter options for these sheets?

A: Standard sheet sizes include 1 m x 2 m and 1.25 m x 2.5 m, with customized sizes offered upon request. Hole diameters range from 0.5 mm to 25 mm, and the open area can be tailored from 10% to 60% depending on specific performance requirements.Q: When should Round Hole Perforated Sheets be used in industrial settings?

A: These sheets are ideal for applications requiring filtration, ventilation, acoustic control, or aesthetic enhancement. Their high strength and uniform perforations make them suitable for demanding industrial environments where durability and performance are critical.Q: Where can these perforated sheets be applied?

A: Round Hole Perforated Sheets find use in various industrial sectors, including manufacturing plants, HVAC systems, architectural facades, acoustic panels, and filtration units. Their versatility allows integration into multiple systems and structures.Q: What is the process for customizing the perforation pattern or sheet specifications?

A: Clients can specify desired sheet dimensions, hole diameter, pitch, open area, edge finishing, temper, color, and surface treatment. The manufacturer designs and produces sheets to match these specifications, ensuring the final product fits the intended application perfectly.Q: How does using Round Hole Perforated Sheets benefit industrial applications?

A: The sheets provide enhanced durability, consistent venting or filtering ability, corrosion resistance, and easy integration. Their tailored features improve operational efficiency, structural longevity, and environmental control in various industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese