MS Perforated Plates

Product Details:

- Process Perforated

- Temper Annealed

- Standard ASTM / IS Standard

- Shape Rectangular, Square

- Surface Treatment Galvanized / Powder Coated

- Usage Industrial

- Material Metal

- Click to View more

MS Perforated Plates Price And Quantity

- 10 Square Foot

- 225 INR/Square Foot

- Up to 1500 mm

- Round, Square, Slot

- As per order

- 1 mm to 25 mm

- Wooden Crate, Bundle, as per requirement

- Smooth, Polished

- Plain / Cut Edge

- Up to 3000 mm

- High

- Silver / Custom Coating Available

MS Perforated Plates Product Specifications

- Annealed

- Perforated

- Industrial filtration, Machine guard, Construction, Ventilation systems

- Hot Rolled

- Metal

- ASTM / IS Standard

- High strength, Corrosion resistance, Uniform perforation

- Rectangular, Square

- 1 mm to 10 mm

- Industrial

- Galvanized / Powder Coated

- Perforated Plate

- Up to 1500 mm

- Round, Square, Slot

- As per order

- 1 mm to 25 mm

- Wooden Crate, Bundle, as per requirement

- Smooth, Polished

- Plain / Cut Edge

- Up to 3000 mm

- High

- Silver / Custom Coating Available

MS Perforated Plates Trade Information

- 100000 Square Foot Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- West Bengal, Sikkim, Odisha, Delhi, Goa, Telangana, Mizoram, Central India, Maharashtra, Chhattisgarh, Nagaland, Madhya Pradesh, East India, Karnataka, Tamil Nadu, Rajasthan, Andhra Pradesh, Arunachal Pradesh, Jharkhand, North India, Dadra and Nagar Haveli, Punjab, Himachal Pradesh, South India, Assam, Haryana, Bihar, Uttarakhand, Gujarat, Tripura, West India, Lakshadweep, Kerala, Daman and Diu, Uttar Pradesh, Pondicherry, , Chandigarh, Jammu and Kashmir, Meghalaya, Andaman and Nicobar Islands, Manipur, All India

Product Description

Description of Mild Steel Perforated Plates

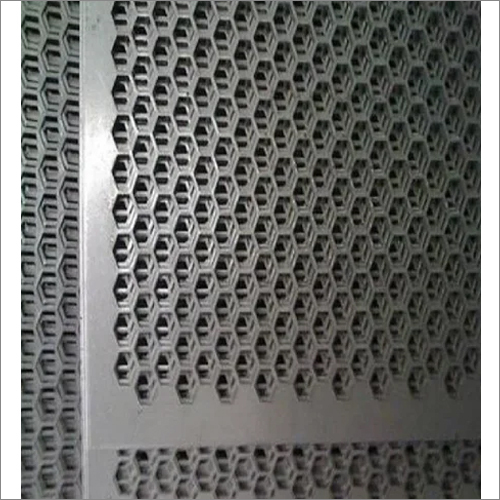

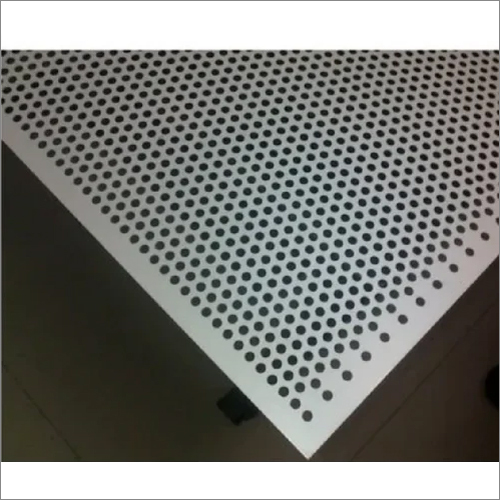

Mild Steel Perforated Plates are metal sheets made from mild steel that feature a pattern of holes or perforations. These plates are widely used in various industries due to their strength, flexibility, and cost-effectiveness. The perforations can be in different shapes, including round, square, rectangular, or custom designs, and are created through a process of punching or laser cutting.

Key Features:

- Material: Constructed from mild steel, known for its malleability, ductility, and relatively low carbon content, making it easy to weld and form.

- Perforation Patterns: Available in various hole shapes and sizes, including round, square, slotted, and custom patterns, depending on the application.

- Thickness: Mild steel perforated plates come in different thicknesses, from thin sheets to heavy-duty plates, to meet different strength requirements.

- Applications: Commonly used in filtration, ventilation, screening, protective guards, acoustic panels, and architectural applications.

- Surface Finish: These plates can be supplied with different finishes, including plain, galvanized, powder-coated, or painted, depending on the required level of corrosion resistance and aesthetic appeal.

FAQs about Mild Steel Perforated Plates

-

What are the standard sizes available for Mild Steel Perforated Plates?

- Standard sizes typically include 4x8 feet, 4x10 feet, and 5x10 feet sheets. Custom sizes can also be fabricated based on specific project needs.

-

What are the typical applications of Mild Steel Perforated Plates?

- These plates are used in a wide range of applications, including filtration, ventilation, soundproofing, protective coverings, and in architectural designs for facades and screens.

-

How does the perforation pattern affect the plates performance?

- The pattern and size of the perforations can influence factors such as airflow, light transmission, strength, and the ability to filter or screen materials.

-

Can Mild Steel Perforated Plates be used outdoors?

- Yes, but mild steel is prone to rusting when exposed to moisture and air. To enhance durability for outdoor use, the plates can be galvanized, powder-coated, or painted.

-

Are there any limitations on the thickness of Mild Steel Perforated Plates?

- Mild steel perforated plates can be made in a wide range of thicknesses, typically from 0.5mm to several millimeters thick, depending on the required strength and application.

-

How are the holes in Mild Steel Perforated Plates created?

- The holes are usually created using punching or laser cutting techniques, which allow for precise and consistent perforations.

-

What surface finishes are available for Mild Steel Perforated Plates?

- Available finishes include plain (bare metal), galvanized, powder-coated, and painted. These finishes can provide varying degrees of corrosion resistance and aesthetic options.

-

How can Mild Steel Perforated Plates be customized?

- Customization options include varying the hole size, shape, and pattern, as well as specifying the thickness, size of the plate, and surface finish to meet specific project requirements.

-

What are the advantages of using Mild Steel Perforated Plates?

- Advantages include cost-effectiveness, versatility in design, ease of fabrication, and the ability to meet both functional and aesthetic requirements in various industries.

-

How should Mild Steel Perforated Plates be maintained?

- Regular maintenance, such as cleaning and applying protective coatings, can help prevent rust and extend the life of the plates, especially when used in outdoor or corrosive environments

Versatile Perforated Hole Shapes

Choose from a variety of hole shapesround, square, or slottailored to your specific application needs. Our perforated plates ensure optimal airflow, filtration, or structural support, making them suitable for industrial filtration, machine guarding, ventilation, and more.

Custom Dimensions and Surface Finishes

MS Perforated Plates are available in multiple thicknesses (1 mm to 10 mm), widths up to 1500 mm, and lengths up to 3000 mm. Choose from smooth, polished finishes or opt for galvanized and powder-coated surfaces, as well as custom coating solutions to enhance longevity and resistance to corrosion.

Quality Standards and Flexible Packaging

Manufactured using hot rolled techniques and meeting ASTM/IS standards, our perforated metal plates guarantee high strength and consistent quality. We offer flexible packaging optionswooden crates, bundles, or as requiredto ensure safe delivery across India.

FAQs of MS Perforated Plates:

Q: How are MS perforated plates manufactured for uniform hole shapes and sizes?

A: MS perforated plates are produced using advanced hot rolling and perforation techniques. Computer-controlled presses ensure precise, uniform holes in round, square, or slot shapes, resulting in consistent perforation and reliable quality for every plate.Q: What is the typical usage of perforated MS plates in industrial settings?

A: These plates are widely used for industrial filtration, machine guards, construction panels, and ventilation systems due to their high strength, corrosion resistance, and ability to regulate airflow or provide protective barriers.Q: When should I opt for a custom coating or surface treatment?

A: Custom coatings like galvanization or powder coating are recommended for environments where enhanced corrosion resistance or specific aesthetic requirements are needed. These treatments extend the products lifespan, especially in harsh or outdoor settings.Q: Where can these perforated plates be used outside of industrial applications?

A: Apart from industrial use, MS perforated plates can also be employed in architectural designs, acoustics, interior decoration, and exterior cladding for buildings, offering both functional and decorative benefits.Q: What is the ordering process and minimum order quantity (MOQ)?

A: Simply contact your chosen dealer, distributor, or manufacturer with your specifications. The minimum order quantity is flexible and can be adjusted according to your project requirements, ensuring a seamless procurement process.Q: How does the choice of hole size and plate thickness affect performance?

A: Selecting the appropriate hole size (1 mm to 25 mm) and thickness (1 mm to 10 mm) impacts the plates strength, airflow, filtration capacity, and structural integration. Our experts can advise on the best configuration for your projects demands.Q: What benefits do customers gain from choosing high-tensile, standardized perforated plates?

A: Customers benefit from reliable load-bearing capabilities, consistent perforation, superior durability, and compliance with international (ASTM/IS) standards, ensuring safety and longevity for industrial and commercial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese